I'll show here how I do bluestuff casting, used in the examples above to use extra arms and heads with Milliput cast bodies to make additional Possessed Space Marines.

Here are the examples primed and zenithal shaded

I dip the bluestuff in a hot water container

This is the consistency you want, be careful not to burn your fingers too badly

I then squish the piece against a blob of bluestuff inside of a lego-built cage

Here is the underside. Lots of times I accidentally squish some details if I press too hard (like in the example above) you can see that some spikes got squished and will result in a damaged master and a hole in the final mold. Oh well too bad, it doesn't happen often if you are careful, and I was distracted by making this tutorial.

Against the light

I pop the whole thing in the Freezer so I can keep moving

I prep the next pellets of bluestuff on hot water

After I remove it from the freezer I make a lego press

I also sparkle in powder to make demolding easier

I spread it around with a brush

Grab more bluestuff

Use pliers to not burn your fingers

I then put the top layer of bluestuff and press firmly with the lego press so that the pressure is even and the top ends up flat

Back in the freezer!

After it cools down I start disassembling the mold cage

flat bottom

The sandwich

The middle was still warm so I propped it back in the freezer

After that I can start to pull the pieces apart slowly, kind of peeling it out

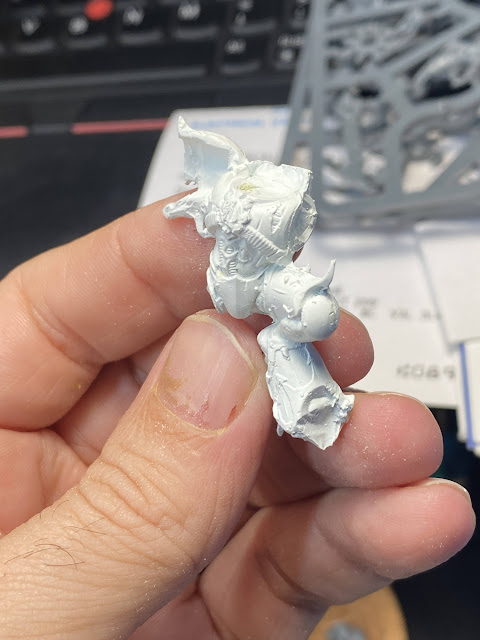

The master piece

I then prepare milliput, my milliput was super old so I have to cut away the cured outer layer

Mix the two parts and start filling in both halves

Use plenty of water and really push it in all the crevices

I then put one atop the other and massage it down to that I spread the milliput around

just keep pressing and massaging it, alternating between a finger squeeze to get excess milliput out as well as flat table presses to "reform" he shape

Any excess goes into the cable/tentacle maker

have loads of this stuff

After the milliput cures a bit (about 40m on my temperature) I remove the top part of the mold to accelerate the drying process

You can use a shaping tool to scrape some of the flash already, they should ideally be a thin film

Scrape away

After about 2 hours you can usually pull the piece out

The piece right out of the mold, still somewhat pliable, I then use a scalpel to cut away the flash and reshape and smooth the mold lines while the milliput is still pliable, as after it completely hardens its much more challenging to do so, though sanding and filing chunks is easier then.

The collar spikes demonstrate how that kind of spindly detail are hard to come by, but also, this is a highly complex shape to pull off

Applied to the model

Original vs Copy

A simpler shape

Out of the mold

After cutting flash, filing and sanding

Painted models

Comments